Count

Your

Warehouse

inDaysHOURS

Start with a phone to replace hundreds of scans with a single capture. Count multiple shelves floor to ceiling in seconds. Scale to drones or robots when you’re ready.

Manual Counts Are the

Silent Killer of Operations.

Every hour spent counting is an hour you can’t ship. Freezing

operations for manual scans kills momentum and costs revenue.

Too Slow

Full counts take days. Your best people spend time hunting labels instead of moving product.

Trapped Capital

Low confidence forces you to carry excess safety stock. That’s millions sitting on shelves.

Phantom Errors

Manual scans often struggle to exceed 90% accuracy at scale. The result? Write-offs, chargebacks, and broken trust.

on the shelf.

In ecommerce, inaccurate inventory turns into canceled orders, late shipments, chargebacks, and lost repeat customers. The same counting problem becomes a customer-trust problem.

There’s a better way,

and it’s already in your team’s pocket.

One PhotoReplaces

Hundreds of Scans.

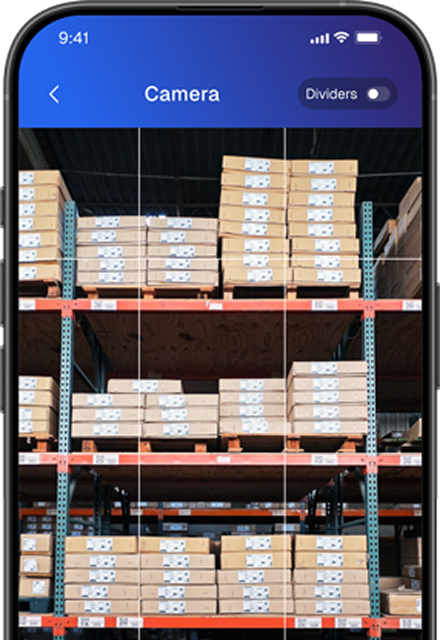

Capture

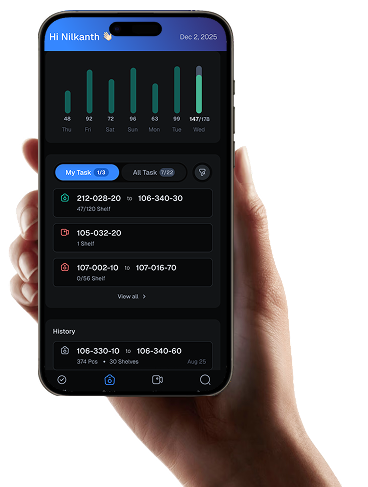

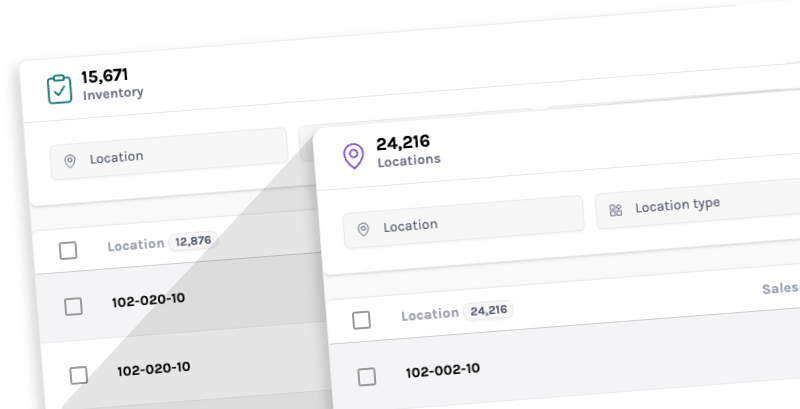

Use phones or existing Zebra scanners to photograph entire aisles in minutes. BinSight counts every product on every shelf, floor to ceiling, in seconds.

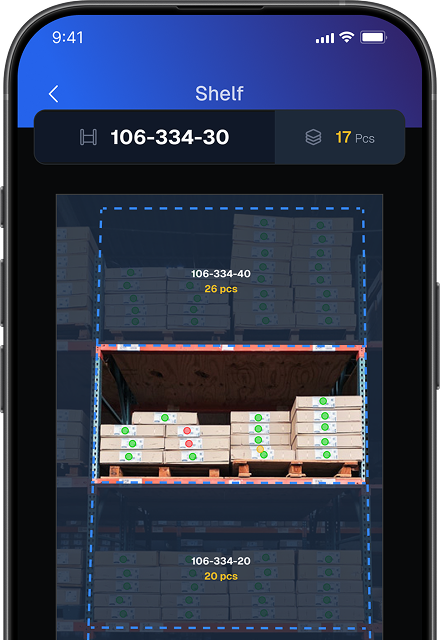

Verify

Review counts visually on-screen. Approve with confidence.

Sync

Send verified counts and shelf space availability directly to your WMS or ERP. No manual entry. No delays.

Imagine inventory staying accurate without freezing operations, teams moving product instead of chasing labels, and confidence replacing“we think it’s here.”BinSight makes that possible.

Start Counting Today with

Phones You Already Have

Get results fast using the cameras already on the floor. Capture shelves as your team walks, verify exceptions, then sync updates back to your systems.

Robot

Always-On PrecisionFor 24/7 autonomous passes and accurate reads on smaller SKU labels, the robot becomes your next chapter.

Drone

Effortless ReachFor quick checks on high or scattered shelves, the drone captures counts without lifts or delays.

What Warehouse Managers and

Finance Leaders Say

One warehouse, two perspectives.

“We used to pull multiple people off the floor to count. Now one person can do it faster, without slowing anyone else down.”

“Inventory errors were costing more than we realized. Once accuracy stabilized, the financial impact became clear quickly.”

See What “Good Enough”

Inventory Is Costing You.

1% combined accuracy miss in a $25M warehouse = $1.25M lost revenue.

Lost Revenue

$20/hr avg labor cost

See It Work in Your

Warehouse.

We'll run a short, focused trial with your team to validate accuracy without disrupting operations.

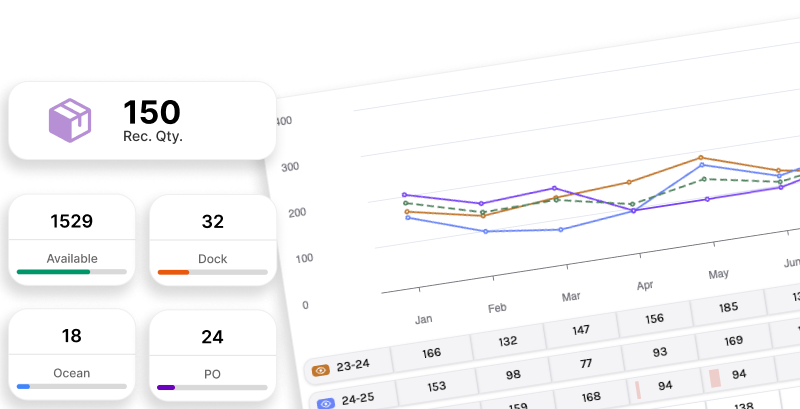

Complete Inventory Optimization

BinSight provides the accurate count. The DataMingle ecosystem uses that data to optimize every other part of your warehouse.

OptiStock

Prevent overstock and stockouts. Analyzes historical data to recommend precise order quantities, ensuring you never run out of best-sellers.

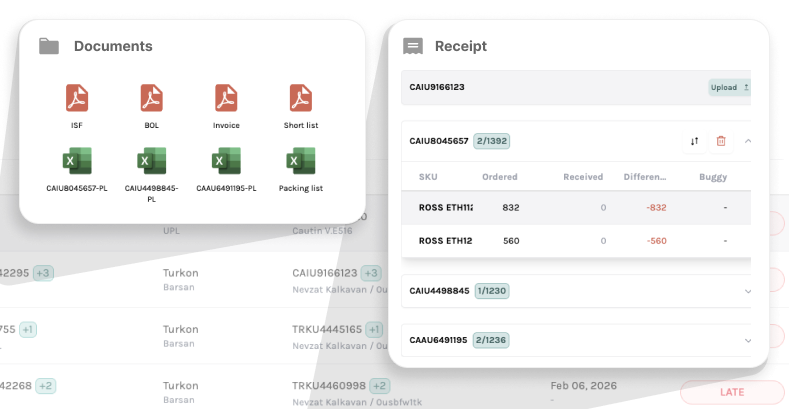

ContainerPro

Prevent overstock and stockouts. Analyzes historical data to recommend precise order quantities, ensuring you never run out of best-sellers.

InventoryFlow

Seamlessly sync inventory feeds to eCommerce platforms (Wayfair, Amazon, Shopify) via API or FTP. No more overselling.

Built byOperatorsEngineered to Scale

50+ years of combined warehouse operations and engineering experience.We run a large distribution operation serving major big-box and e-commerce retailers. We deal with the same realities as our customers: chargebacks, stockouts, tied-up capital, and pressure to trust inventory that drives daily decisions.

The problem isn’t effort, it’s the tools. Manual counts disrupt operations. Scanning doesn’t scale. So we built BinSight: fast, visual inventory counting using devices already on the floor, designed to fit how warehouses actually run today and scale from phones to robots without changing workflows.

BinSight is built and tested in real operations, every day, with one goal: inventory you can trust, without slowing the warehouse down.

Peace of mind, profit, and precision. BinSight is the tool I wish I had years ago.